Assisting in the new trend of HVAC installation, Wenger shines in the York VRF "100% Construction Site" National Competition

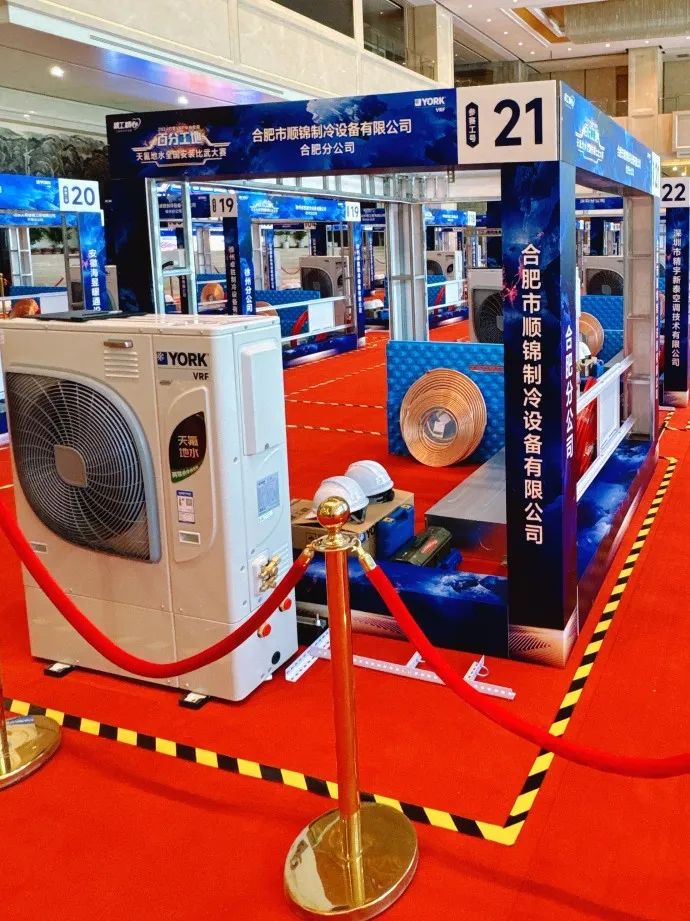

Under the dazzling lights of the ancient capital Xi'an, a grand feast of professionalism, craftsmanship, and innovation - the York VRF "100% Construction Site" Tianfu Dishui National Installation Competition - kicked off. This event is jointly organized by the China Refrigeration and Air Conditioning Industry Association and Qingdao Johnson Controls Air Conditioning Co., Ltd. This is not only a peak competition that gathers 39 elite installation teams from across the country, but also a brilliant intersection of technology and art in the field of HVAC installation. On this land full of historical heritage, every team interprets their relentless pursuit of perfect installation with the fullest enthusiasm and the most exquisite skills.

At this grand event, many industry experts gathered together, including Mr. Ma Guangyu, Vice President of Hefei General Machinery and Electrical Product Testing Institute, Deputy Secretary General of China Refrigeration and Air Conditioning Industry Association, and General Manager of Beijing Zhongliangtong Quality Certification Center Co., Ltd., Mr. Wang Xuebin, General Manager of Qingdao Johnson Controls Air Conditioning Co., Ltd., and Mr. Cao Dawei, General Manager of Customer Service Department. They took the stage one by one and delivered insightful speeches.

General Manager Cao Dawei focuses on the field of customer service and elaborates on the core idea of precision craftsmanship: being skilled in craftsmanship, precision in specifications, precision in tools, precision in materials, precision in workmanship, and precision in tuning.

In this arena of fierce competition, Wenger has become the center of attention with his outstanding products and innovative ideas. Wenger made a stunning appearance with his "meticulously crafted" internal machine auxiliary material package and covered signal cable, adding a bright color to the competition and providing unprecedented support and assistance to the participating players.

The 'exquisite and meticulous' internal machine auxiliary material package is another masterpiece of Wenger's commitment to quality. It is not just a set of auxiliary materials, but also a comprehensive upgrade to the installation process. From material selection to design, every step embodies Wenger's ultimate pursuit of details, ensuring a smoother installation process and more reliable product quality. This is not only a blessing for the professional ability of the installation team, but also a commitment to a comfortable life for every user.

The covered signal line is another milestone in Wenger's technological innovation, as its feature of not requiring on-site pipe threading processing effectively improves the construction efficiency of the players. It adopts dual shielding technology, effectively improving the stability and anti-interference ability of signal transmission, ensuring more accurate and error free intelligent control of the air conditioning system.

On the stage of "100% construction site", Wenger's products not only became good helpers for the participating teams, but also won unanimous praise from the on-site expert judges and audience for their excellent performance and quality. This is not only a powerful proof of Wenger's product strength, but also a vivid interpretation of Wenger's brand philosophy of "serving a better life".

In the future, Wenger will continue to explore and innovate, bringing more revolutionary products and technologies to the HVAC installation industry. We believe that future installation sites will become more standardized and intelligent, providing users with a more comfortable, energy-efficient, and environmentally friendly living experience.

Please first Loginlater ~